Morning performance management meetings at this leading mining operator are vital for tracking progress against targets and planning operations. Fujitsu Data & AI helped the company to optimise and digitise the data platform and process to deliver significant improvements.

Challenge

Performance management meetings depended on manual processesand paper charts. The process was time-consuming and data could beout of date, unreliable or difficult to digest for decision-making.

Solution

The company worked with Fujitsu Data & AI to digitise and automate data for morning meetings, delivering timely and accurate visualisations to a large-scale video wall to enable actionable insights.

Outcomes

- Morning meeting times now halved

- Accurate, timely data improves operational outcomes

- Staff can now focus adding value rather than reporting

“The improvement in data integrity is highly important, as is getting the time back so people can actually focus on adding value rather than just reporting.”

Spokesperson, leading mining and metals business

50%

reduction in meeting times

15

minute refresh rate improves data accuracy

- Industry: Mining

- Location: Australia

About the customer

This leading mining and metals company headquartered in Western Australia

produces commodities including bauxite, alumina, aluminium, copper, silver,

lead, zinc, nickel, metallurgical coal and manganese from operations in Australia,

Africa and South America. It has development options in North America and

partnerships with junior explorers around the world.

Creating stakeholder value

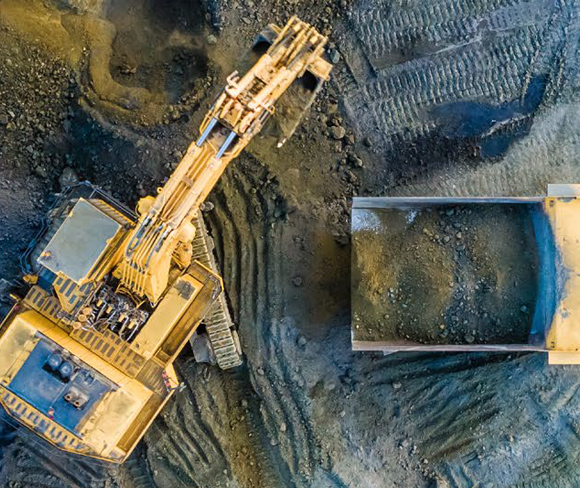

As a country rich in natural resources, it is little surprise that mining is a foundational sector of Australia’s economy. The industry employs around 286,000 people and represents around 10% of Australia’s GDP and over 60% of its total export revenue.

One leading mining business operates sister underground mines in the eastern Australian states. Their principal output is metallurgical coal for use in steel production, and the high quality of the coal produced means it commands a premium market price.

The company behind the mines specialises in extracting a range of minerals including bauxite, aluminium, copper, silver and lead from operations in Australia, Africa and

South America.

The company believes the extraction and processing of minerals and metals can and should be carried out responsibly. Its mission is to minimise the impact of its activities while creating value for all stakeholders at each stage of the mining lifecycle. Likewise, any time-saving or better-quality data that informs key decisions stands to deliver immense value to its stakeholders.

A compelling case for digitisation

As with many other mines, each day begins with a performance management meeting. It provides an important opportunity for senior management and key staff to assess the mine’s performance over the previous days, track performance against plans and targets, troubleshoot any issues and set operational objectives for the coming days.

“We have daily reviews on production and safety performance, and historically we would manually grab input from multiple standalone source systems,” explains the company spokesperson. “For instance, our safety performance information was in one area, our production performance data was in another area and our maintenance performance was in another. They didn’t talk to each other.”

The 30-to-40-minute meetings previously involved printed charts, graphs and statistical analysis pinned to the meeting room wall, onto which notes and comments were added

manually. It was a time-consuming process and prone to inaccuracy and error.

“Imagine 20 people in a room standing 10 metres back looking at a little graph no bigger than an A3 piece of paper,” the spokesperson adds. “You can’t really read what’s on the on the charts from that distance, so they become pretty much ineffective.”

The company saw a compelling business case to digitise the process, connect the disparate systems and pull the necessary information so it was accessible and delivering meaningful insights in near-real time. More importantly, the solution had the potential to give time back to already-stretched mine personnel to do more value-added work.

Revamping the data-collection process

The company had already worked with Fujitsu Data & AI to develop a data platform for its global corporate-level operation. The new cloud-based solution was designed to give improved access to data from individual mines, with the initial twin mines acting as pilots before extending the concept to other operations across the business.

It was a system that was beginning to deliver impressive results. It also provided a starting point from which the company could work with Fujitsu Data & AI to build a platform to transform the daily morning meetings.

“Our original process was good and we were very clear that didn’t want to lose that, but it wasn’t very efficient,” the spokesperson notes. “We wanted to take the manual intervention out and use technology to get a more efficient result. That was the key decision.”

The spokesperson continues: “We had a vision of what we wanted, but not the technical expertise to execute it. We explained the scope and what we were trying to achieve to Fujitsu and looked to their expertise to create it and provide recommendations based on similar operations.”

The company worked with Fujitsu Data & AI to identify the key indicators that brought value to the meetings, access the systems holding the relevant data, tighten up data-collection processes and design a series of charts and infographics that would be updated in near-real time. These could then be fed into the meetings and displayed on 65-inch screens, providing compelling visualisations of critical areas of performance backed up by previously unavailable data speeds and accuracy.

Quick and efficient, accurate and timely

At the pilot mines, previously time-consuming tasks that made up morning meetings have been replaced by quick, efficient and digitally driven insights.

Instead of manually compiled data, automated processes populate pre-designed charts in near-real time, taking the data directly from the source, and display them on the new meeting room video wall. Participants can zoom in on particular data points and be confident that they are both accurate and timely.

“All of a sudden, the manager in the room now can see at a glance where things are on or off track and determine actions to put in place to address any issues,” the spokesperson explains. “That’s a key improvement. It’s much more visual than it was before and it promotes better outcomes.”

Crucially, meetings that once took up to 40 minutes have now halved in length, while the quality and value of the information shared have improved significantly. From production output to stoppages, safety processes and risk management, company staff can ensure that targets are met and plans are followed based on reliable data.

“The improvement in data integrity is highly important, as is getting the time back in the morning so people can actually focus on higher value add work rather than just reporting,” the spokesperson concludes. “And if you’d seen how crazy those morning meetings were, that’s a huge step forward in time saving.”