Sustainable Manufacturing

"Growth Beyond" - Connecting the Virtual and Real Worlds to Accelerate Change in the Era of Resilience

Today, companies are required to respond flexibly to changes in the business environment, taking uncertainty into account. By simulating scenarios that take uncertainty into account in the virtual world and quickly feeding them back into the real world, companies can make decisions with certainty and speed in terms of various risks and costs.

The integration of digital data will also enable the creation of new ecosystems, such as supply chain resilience and reduction of GHG emissions in society as a whole.

The new generation of manufacturers is driving towards

Taking social and environmental responsibility

Transition to net zero, climate change, industrial pollution, well-being, racial injustice, or inequality come to the fore of business action

Going circular to take advantage of new markets

Removing waste in the production process, reusing and recovering products and materials, regenerating natural resources and systems

Meeting changing consumer purchasing patterns

The current and future generations are demanding sustainable practices from companies they work from and buy from

Bringing manufacturing back home

Manufacturers are moving operations back to their country, as many consumers believe that locally made products are high in quality and support the country’s economy

Responding to changes in demand channel

A strong ecosystem can avoid supply chain issues caused by rising customer expectations of shorter lead times, expanded products and services, and tailored experiences

Reducing pricing and de-risking the business model

Sustainable manufacturing is becoming a cost-saving option. Sustainable approaches are becoming more financially viable and risk-resilient

With a 'human-centric' approach and advanced digital twins, a new paradigm shift in manufacturing is realized - achieving an 'Integrated Sustainable World'

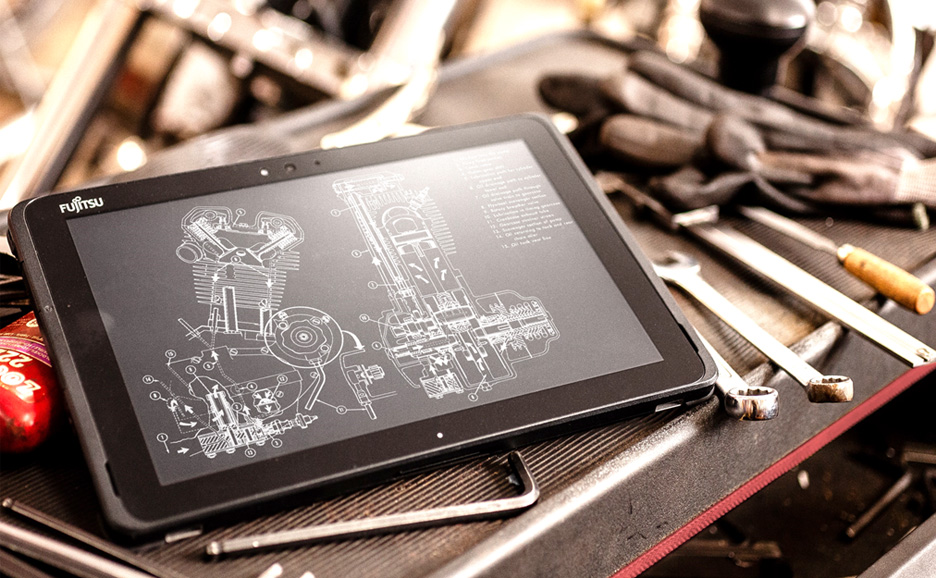

Digital Engineering Chain

Seamlessly connecting customers and markets to deliver needed products and services in a timely and efficient manner and to achieve sustainable design and development that minimizes lifecycle energy.

Featured offerings

We will establish a development process to bring products to market at the right time in line with social changes.

Digital Supply Chain

We realize a system that speeds up decision-making across the supply chain with End-To-End supply chain planning adaptable to market changes and expanding manufacturing stakeholders, and quality management that focuses on high quality and environmental consideration.

Featured offerings

The manufacturing industry is required to make various efforts and improvements in order to respond quickly to social changes, diversifying markets, and customer needs, as well as to manufacture to the minimum necessary for a recycling-oriented economy. We create a loop of improvement by converting information from all business areas into data that can be combined, optimizing various plans, making improvements based on quantitative judgments, and spreading the effects of these improvements from one department to other departments and bases.

Aiming to improve the labor environment and enhance the competitiveness of medium and small-sized enterprises using IT, we provide manufacturing solutions that enhance productivity and quality using SAP S/4HANA® Manufacturing for Production Engineering and Operations.

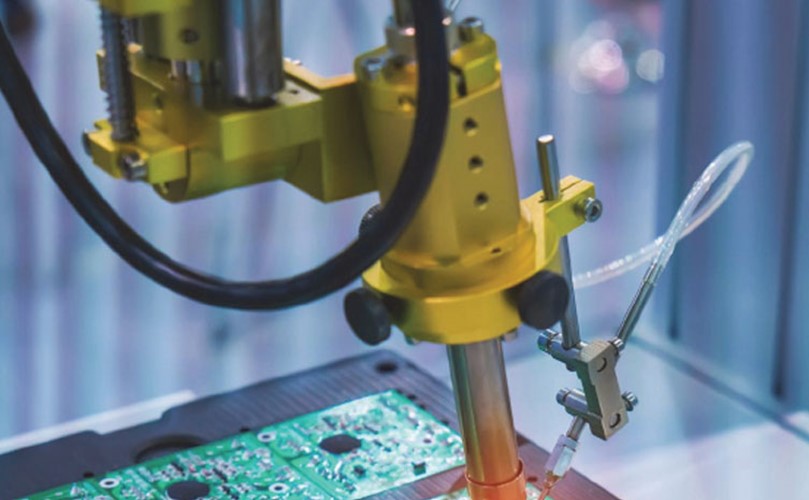

Digital Factory

We work with the end-to-end business value chain in a sustainable way across the entire operation, with a particular focus on the lack of skilled labor in the factory and the effective utilization of labor.

Featured offerings

We support productivity improvement and defect reduction by quantitatively understanding bottlenecks in factories and processes and early identification of root causes. We also ensure secure management of OT assets and data-driven decision-making through a secure digital factory cloud infrastructure.

We prevent factory issues by monitoring factories, lines, and equipment, predicting the future from past information, and resolving problems in advance with alarms and suggestions.

Digital Customer Chain

Collaborate with customers and markets to enable more insightful decision making and increase your competitiveness in the marketplace

ESG Strategy

We provide services to visualize and analyze risks and issues, and support the development of strategies to launch sustainability businesses across industries. We aim to contribute to society by building sustainable business models while minimizing environmental impact and enhancing corporate competitiveness.

Featured offering

ESG Strategy - GHG visualization and reduction

Circular Eco System

We support proactive measures for risks in complex supply chains and quick decision-making during occurrences, aiming to reduce business losses.

Featured offerings

Aiming to activate the recycling market by collecting environmental data on products to comply with European battery regulations and providing a digital passport with information from manufacturing to recycling.

Sustainable Manufacturing solutions

React at speed to customer demands

Leverage strategic partnerships